In today’s competitive marketplace, packaging is far more than a protective layer it is a strategic branding and communication tool. Studies show that consumers make purchasing decisions in as little as 7 seconds, meaning packaging plays a pivotal role in influencing choices. Flexographic printing solutions have emerged as one of the most reliable and efficient technologies for modern packaging, delivering high-quality results at scale across multiple industries.

This comprehensive guide explores:

-

How flexographic printing works

-

Its advantages and sustainability benefits

-

Innovations shaping its future

-

Choosing the right printing partner

-

Industry-specific applications

By the end, brands will understand why flexographic printing is a core technology in modern packaging strategy.

Why Flexographic Printing Matters Today

Flexographic printing, commonly referred to as flexo printing, uses flexible relief plates and fast drying inks to produce high-quality packaging across a wide range of substrates. It is widely used for:

-

Labels

-

Flexible packaging (pouches, wrappers)

-

Folding cartons

-

Corrugated materials

Flexo printing supports brand visibility, customization, and sustainability through:

-

Eco-friendly inks

-

Renewable substrates

-

Efficient production workflows

Recent innovations including digital-hybrid presses, automation, and advanced quality control systems have made flexo printing faster, more precise, and less wasteful, addressing both commercial and environmental priorities.

Understanding Flexographic Printing Technology

Flexographic printing machine is a modern evolution of traditional relief printing, designed to handle high-speed, high volume production while maintaining consistent quality across porous and non porous materials. Unlike traditional printing methods, flexo combines versatility, speed, and adaptability, making it ideal for diverse packaging applications.

What Is Flexographic Printing?

Flexographic printing uses flexible photopolymer plates mounted on rotating cylinders. Ink is transferred from an anilox roll to the raised areas of the plate, and then onto the substrate. This process enables:

-

Precise ink control

-

Sharp image reproduction

-

Rapid drying

Common substrates for flexo printing include:

-

Plastic films

-

Paper and paperboard

-

Foil and laminates

-

Corrugated packaging

Flexo’s adaptability to various materials is one of its core strengths, especially in industries requiring high-quality and durable packaging.

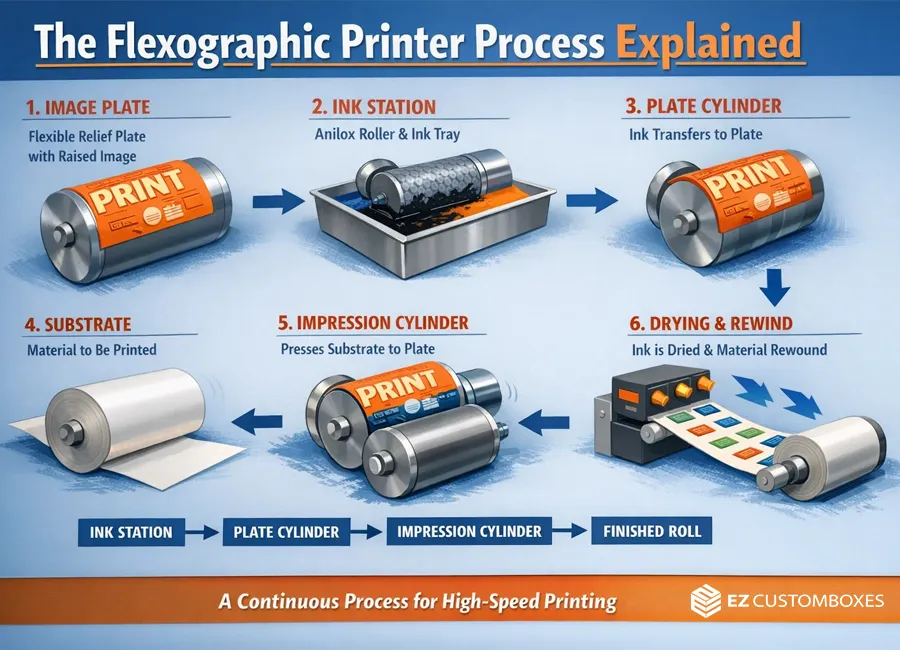

The Flexographic Printer Process Explained

The flexographic printer involves several steps, each critical for achieving consistent and vibrant print results.

1. Plate Creation

The flexographic printing plates are produced with raised image areas. These plates are durable and precise, capable of withstanding high-speed press operations without losing image fidelity.

2. Ink Transfer

The anilox roll delivers a controlled and precise amount of ink to the plate. The engraved cells of the anilox roll regulate ink distribution, preventing oversaturation or uneven coverage.

3. Printing

Ink from the plate is transferred to the substrate in a continuous, high-speed process. Flexo presses can handle large volumes efficiently while maintaining image quality and color accuracy.

4. Drying & Curing

Fast drying inks and advanced curing systems allow for immediate handling and post-processing, minimizing downtime and ensuring rapid production cycles.

Essential Components of Flexographic Printing

Photopolymer Plates

Modern plates maintain image clarity at high speeds, ensuring reliable print quality over long runs.

Anilox Rolls

These rolls regulate ink volume and distribution, enabling consistent and sharp images on diverse substrates.

Flexographic Inks

Flexo inks are formulated for different applications:

-

Water based inks: Eco-friendly, widely used in food and consumer goods packaging

-

Solvent based inks: Durable and versatile for specialty materials

-

UV curable inks: Fast curing and high-performance for premium packaging

Ink selection impacts print quality, regulatory compliance, and environmental footprint, which is critical for brands aiming to meet sustainability goals.

Key Advantages of Flexographic Printing Solutions

Flexographic printing offers several advantages that make it the go to solution for modern packaging.

1. Versatility Across Substrates

Flexo printing works on porous and non porous materials, including plastic, paper, foil, and corrugated cardboard. This versatility allows brands to use a consistent print method across different product lines.

2. High-Speed Production

Fast-drying inks and continuous roll-fed presses enable efficient, large-volume production, ideal for meeting tight deadlines and scaling seasonal campaigns.

3. Cost-Effectiveness

Flexo printing minimizes downtime and is economical for long print runs, reducing overall production costs while maintaining high quality.

4. Environmentally Responsible

Water-based inks, minimal waste, and recyclable substrates make flexographic printing a sustainable packaging solution, aligning with corporate environmental commitments.

Role of Flexographic Printing in Modern Packaging

Enhancing Brand Visibility

Studies reveal that color and design account for up to 70% of purchasing decisions. Flexo printing delivers:

-

Vibrant colors

-

Sharp text

-

Consistent brand imagery

This ensures packaging stands out on crowded retail shelves and communicates brand identity effectively.

Customization and Personalization

Flexo printing allows brands to:

-

Produce limited-edition packaging

-

Launch seasonal or promotional designs

-

Quickly adapt to market trends

Such flexibility supports personalized consumer experiences, fostering brand loyalty.

Supporting Sustainable Packaging Goals

Environmental responsibility is now a key purchase driver. Flexo printing enables brands to:

-

Use eco-friendly inks

-

Select recyclable or biodegradable substrates

-

Reduce ink waste through precise application

This combination of efficiency and sustainability helps companies meet regulatory standards and consumer expectations.

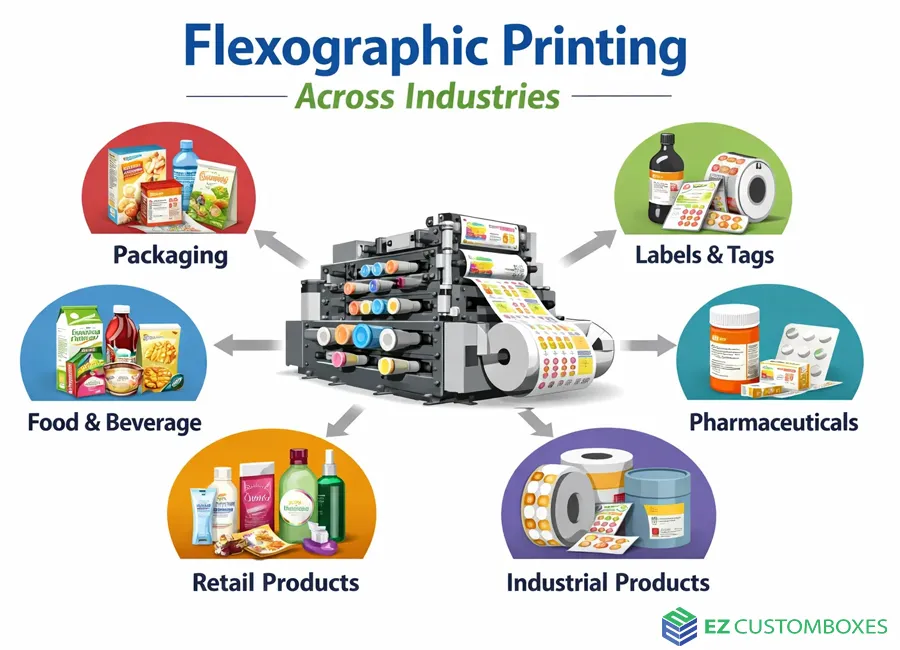

Flexographic Printing Across Industries

Food & Beverage Packaging

-

Food-safe inks for consumable goods

-

Flexible pouches, wrappers, and cartons

-

High-volume production for seasonal demands

Pharmaceuticals

-

Precise labeling and barcoding

-

Compliance with stringent industry regulations

-

Packaging that protects product integrity

Cosmetics & Personal Care

-

Premium finishes for aesthetic appeal

-

Durable labels for long shelf life

-

High-resolution graphics for brand differentiation

Retail & E-commerce

-

Durable packaging for shipping and handling

-

Eye-catching designs for online marketplaces

-

Cost-efficient solutions for variable volumes

Flexographic printing’s adaptability ensures consistent branding and quality across all product categories.

Innovations Shaping the Future of Flexographic Printing

Digital Hybrid Flexographic Printing

Digital integration enables:

-

Short-run production

-

Rapid design adjustments

-

Enhanced precision

This hybrid approach combines flexo’s speed with digital flexibility, supporting niche markets and testing new packaging designs.

Advanced Ink and Plate Technologies

Modern inks and plates offer:

-

Improved adhesion and durability

-

Finer detail reproduction

-

Faster curing times

UV-curable inks and photopolymer plates have broadened application possibilities while maintaining sustainability and quality.

Automation and Smart Press Systems

Automation enhances production efficiency through:

-

Real-time print quality monitoring

-

Predictive maintenance to avoid downtime

-

Material waste reduction

These smart systems ensure reliable, high-quality output with minimal human intervention.

Advanced Quality Control Systems

Advanced inspection technologies, including cameras and sensors, detect defects instantly, ensuring consistent, high-quality production while minimizing reprints and waste.

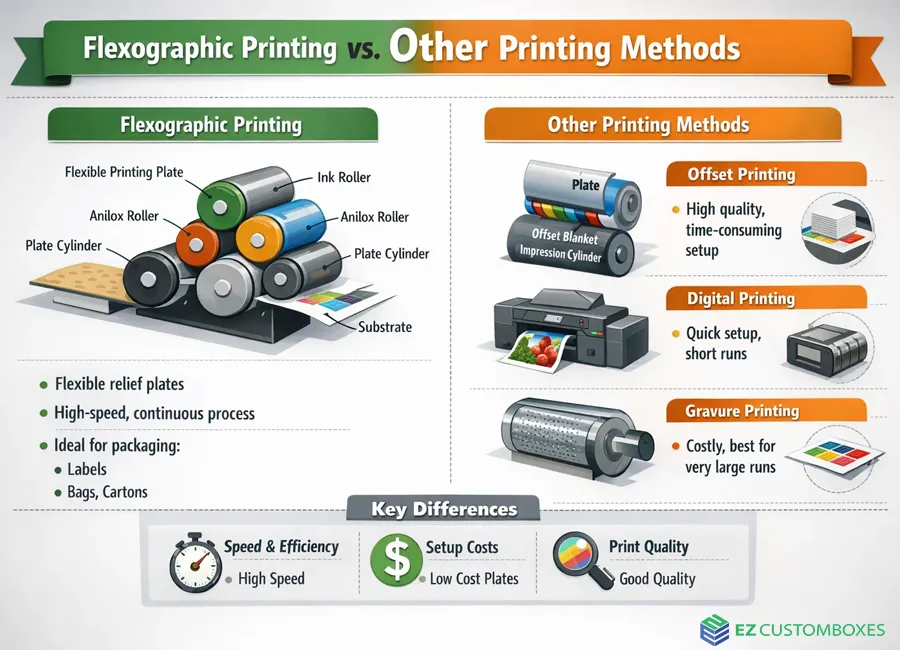

Flexographic Printing vs. Other Printing Methods

While flexographic printing is a top choice for modern packaging, it’s important to understand how it compares to other printing technologies like digital printing, gravure printing, offset printing, and screen printing. This comparison helps brands make informed decisions based on quality, cost, substrate type, volume, and sustainability goals.

1. Flexographic Printing vs. Digital Printing

Digital Printing Overview:

-

Digital printing applies ink directly onto the substrate using inkjet or laser technology, eliminating the need for physical plates.

-

Ideal for short runs, on-demand printing, and highly customized designs.

Comparison:

| Feature | Flexographic Printing | Digital Printing |

|---|---|---|

| Best for | High-volume production of labels, pouches, cartons | Short runs, personalized packaging, variable data |

| Print speed | Extremely high; continuous roll-fed presses | Slower than flexo for large volumes |

| Plate requirement | Requires photopolymer plates | No plates required |

| Cost-effectiveness | Economical for long runs | More cost-effective for small, custom runs |

| Color consistency | Excellent for repeatable high-volume runs | Slight variations possible over multiple prints |

| Substrates | Plastic, paper, foil, corrugated cardboard | Paper, cardstock, limited flexible films |

| Sustainability | Water-based inks, less waste for large runs | Minimal setup waste, but ink types may vary |

Industry Use Case:

-

Flexo is preferred for grocery packaging, beverage labels, and corrugated boxes.

-

Digital is ideal for limited-edition designs, personalized gift packaging, and test marketing campaigns.

2. Flexographic Printing vs. Gravure Printing

Gravure Printing Overview:

-

Gravure uses engraved cylinders to transfer ink directly to the substrate.

-

Known for superior image quality and long, continuous runs.

Comparison:

| Feature | Flexographic Printing | Gravure Printing |

|---|---|---|

| Best for | Versatile packaging applications | Extremely high-quality images, long-run production |

| Print speed | High-speed; efficient for large runs | Comparable high-speed; better for very long runs |

| Cost of setup | Moderate; plates cheaper than gravure cylinders | High; engraved cylinders are expensive |

| Substrate flexibility | Works on plastics, paper, foil, corrugated | Works on paper, flexible films; less ideal for corrugated |

| Maintenance | Plates are replaceable and lower-cost | Cylinders require specialized maintenance |

| Color quality | High-quality, good for vibrant designs | Superior color fidelity and detail, ideal for high-resolution graphics |

| Sustainability | Water-based inks reduce environmental impact | Typically solvent-based inks; more waste and environmental impact |

Industry Use Case:

-

Gravure is common in premium packaging, beverage labels, and flexible film wraps for consumer goods.

-

Flexo is chosen for versatility across materials and cost efficient medium to large runs.

3. Flexographic Printing vs. Offset Printing

Offset Printing Overview:

-

Offset printing transfers ink from a plate to a rubber blanket and then to the substrate.

-

Best suited for high-resolution, large-area prints on paper or cardboard.

Comparison:

| Feature | Flexographic Printing | Offset Printing |

|---|---|---|

| Best for | Flexible and rigid packaging | Paperboard cartons, books, brochures |

| Plate requirement | Photopolymer plates | Aluminum plates |

| Substrate range | Wide: plastic, foil, paper, corrugated | Limited: primarily paper-based substrates |

| Print speed | High-speed production | Moderate; slower than flexo for large rolls |

| Cost-effectiveness | Economical for long runs across diverse materials | Cost-effective for medium-to-large print runs on paperboard |

| Ink options | Water-based, solvent-based, UV-curable | Oil-based, UV, or water-based inks |

| Quality | High-quality images; flexible for multiple substrates | Very high-resolution images; consistent for paperboard and labels |

Industry Use Case:

-

Offset printing is common for folding cartons, printed boxes, and marketing materials.

-

Flexo is chosen for labels, flexible films, and corrugated packaging.

4. Flexographic Printing vs. Screen Printing

Screen Printing Overview:

-

Screen printing pushes ink through a mesh stencil onto the substrate.

-

Excellent for thick ink layers, specialty finishes, and small-batch runs.

Comparison:

| Feature | Flexographic Printing | Screen Printing |

|---|---|---|

| Best for | High-speed packaging runs | Specialty effects, textured surfaces, small runs |

| Ink application | Thin, precise ink layers | Thick ink layers for tactile or glossy effects |

| Substrate flexibility | Plastic, paper, foil, corrugated | Plastic, glass, textiles, ceramics |

| Production volume | Ideal for medium-to-high volumes | Small-to-medium batches |

| Detail and resolution | Excellent, sharp images | Moderate; limited for very fine details |

| Special effects | Limited to standard inks and coatings | Metallic, glitter, 3D textures possible |

| Cost-effectiveness | High for long runs | Cost-effective for small or specialty runs |

Industry Use Case:

-

Screen printing is common in premium cosmetics, specialty packaging, and promotional products.

-

Flexo printing is preferred for mass-market packaging with consistent, efficient output.

Key Takeaways

-

Flexo printing excels in versatility, speed, sustainability, and medium-to-high-volume packaging.

-

Digital printing is best for customization, short runs, and rapid design changes.

-

Gravure printing offers superior image quality but is costlier to set up and maintain.

-

Offset printing works best for high-resolution paperboard products.

-

Screen printing is ideal for specialty finishes, textures, or small-batch projects.

Brands often combine technologies depending on run size, design complexity, substrate, and sustainability requirements. For example, a company may use flexo for high volume packaging and digital for seasonal or promotional packaging.

How to Choose the Right Flexographic Printing Partner

Selecting the right partner ensures brands can maximize the benefits of flexographic printing.

Proven Experience and Expertise

Choose a printer with:

-

Years of industry experience

-

Knowledge of material selection, color management, and regulatory compliance

-

Case studies demonstrating successful projects

Advanced Technology and Capabilities

Evaluate partners based on:

-

State-of-the-art presses and digital workflows

-

Ability to handle small and large production runs

-

Use of automation and advanced inks

Commitment to Sustainability

A responsible partner should provide:

-

Eco-friendly inks and substrates

-

Recycling programs and waste reduction

-

Energy-efficient operations

Reliable Customer Support

Strong communication and support are vital for:

-

Project transparency

-

Timely updates on production

-

Problem resolution and collaboration

FAQs :

1. What is flexographic printing best used for?

Flexo printing is ideal for labels, flexible packaging, folding cartons, and corrugated materials, especially for high-volume production.

2. Is flexographic printing environmentally friendly?

Yes. Modern flexo printing uses water based inks and supports recyclable or biodegradable substrates.

3. How does flexographic printing compare to digital printing?

Flexo printing is cost-effective for long runs, while digital printing excels in short run, customizable designs. Hybrid presses combine both advantages.

4. Can flexographic printing produce high resolution images?

Yes. Modern flexographic technology delivers sharp text, vibrant colors, and consistent print quality, suitable for premium packaging.

5. Which industries commonly use flexographic printing?

Flexo printing is widely used in food & beverage, pharmaceuticals, cosmetics, personal care, retail, and industrial packaging.

Conclusion

Flexographic printing solutions have become a critical component of modern packaging, combining technical precision, operational efficiency, and environmental responsibility. As research and industry case studies demonstrate, flexo printing enables brands to produce packaging that maintains consistent quality across a variety of substrates including paper, plastics, foils, and corrugated materials while supporting sustainable practices through water-based and UV-curable inks.

Advancements such as digital hybrid presses, automation, and real time quality control systems allow companies to achieve high resolution, vibrant prints with minimal waste and faster production cycles. Partnering with an experienced, technology driven flexographic printer ensures expertise in material selection, regulatory compliance, design optimization, and workflow management, providing reliable results for both high volume and customized packaging projects.

In a competitive marketplace where consumer attention and sustainability are paramount, flexographic printing is more than a printing method it is a strategic, expert driven tool that empowers brands to innovate, differentiate, and thrive while delivering durable, visually compelling, and environmentally responsible packaging.

Ethan Robert works at EZ Custom Boxes as their digital marketing manager. Having a solid background in SEO, content strategy, and eCommerce growth, he specialises in using creative packaging content and data-driven campaigns to drive online visibility and brand interaction.