There are many printing options available and knowing the right one to get can help a brand end up with eye-catching and attractive packaging. It is important to impress potential consumers and print coating helps here. Print coating is a necessary part of packaging as it aids the packaging design in looking amazing even if many people come into contact with it. Aqueous (AQ) coating is a popular one in the market. You may be wondering what is aqueous coating?

Aqueous coating is a water-based coating which gets applied to a press sheet. The varnish procedure ensures the end product stands out on the page. The product can even be kept safe from scratches and fingerprints that can negatively impact its attractive appearance.

You might want to compare aqueous coating vs UV coating. These are popular coating options. Aqueous coating tends to be water-based and is more flexible and eco-friendly when compared to UV coating that is chemical-based. It is less flexible than aqueous coating. AQ coating is better for food packaging or general use whilst UV coating can be more effective for luxury packaging.

What is Aqueos Coating?

Aqueous coating is when water-based liquid varnish gets applied to printed materials when the printing process is going on. This protects the printed materials and makes them look appealing. The printing is regarded as being eco-friendly.

The primary components of aqueous coating include water along with water-soluble polymers or resins which become the protective film. There are additives like waxes, pigments, and surfactants. These aim to dry quickly to give the packaging a durable finish.

Water behaves like the solvent or carrier whilst the water-soluble polymers include acrylics and polyurethanes. Additives that are included like waxes make the packaging design be slip resistant and the pigments are added for color or opacity. Therefore aqueous coating for printing can be beneficial.

Semantic entities included:

- Water-based coating - This means a clear and water-based liquid such as paint gets applied on the printed material. The coating employs water like its main carrier which has polymers plus additives that make up the protective layer. This protects the box from smudges and scratches and enhances print vibrancy. It is therefore even more eco-friendly than oil-based varnishes.

- Printing Industry - This is a business which makes physical printed materials including books, newspapers, business cards, modern packaging, etc. Different printing methods are included here such as aqueous coating for printing.

- Eco-friendly coating - This is a surface finish made to limit environmental damage. It does this by employing a water-based liquid coating. It has low Volatile Organic Compounds or VOCs. This makes it a more eco-friendly alternative when compared to solvent-based options.

- Protective finish - This includes adding a clear water-based varnish upon printed materials to keep them safe from damage like scratches, fingerprints, etc. whilst giving the box a gloss, matte, and satin finish.

How Does Aqueos Coating Work?

The process includes applying a quick-drying, water-based varnish on printing materials inline. This occurs when the printing process is occurring. Rollers are employed to spread a layer which gets dried by heat. This becomes the protective and clear film that makes the appearance of aqueous gloss coating or matte aqueous coating.

Step-by-step process

- Standard offset printing is able to make the base design upon the printed material which can include paper or board.

- Immediately after the printing process has occurred and when the sheet is wet, there is a dedicated coating unit that then applies the particular aqueous coating. Aqueous coating in printing is therefore important.

- The coated sheet is heated with a dryer or even a heated oven. This is able to evaporate the water fast so that the solid polymer film is left behind.

- After this the material can get cut, folded, etc.

Application methods

Inline- This is a printing process that includes applying clear, water-based protective coating on the printed sheet that occurs at the same time like the printing ink. It happens in the same pass. It employs a dedicated coating unit that gets integrated within the printing press.

Offline- This includes applying the coating on the printed sheets like a separate post-press procedure. It occurs when the printing inks are totally dried.

Flood Coating- AQ flood coating includes applying the protective, water-based coating to access the complete surface of the particular printed piece and that inline with the printing press. There will be a uniform layer that provides the box with durability making it scuff resistance as well as visually attractive.

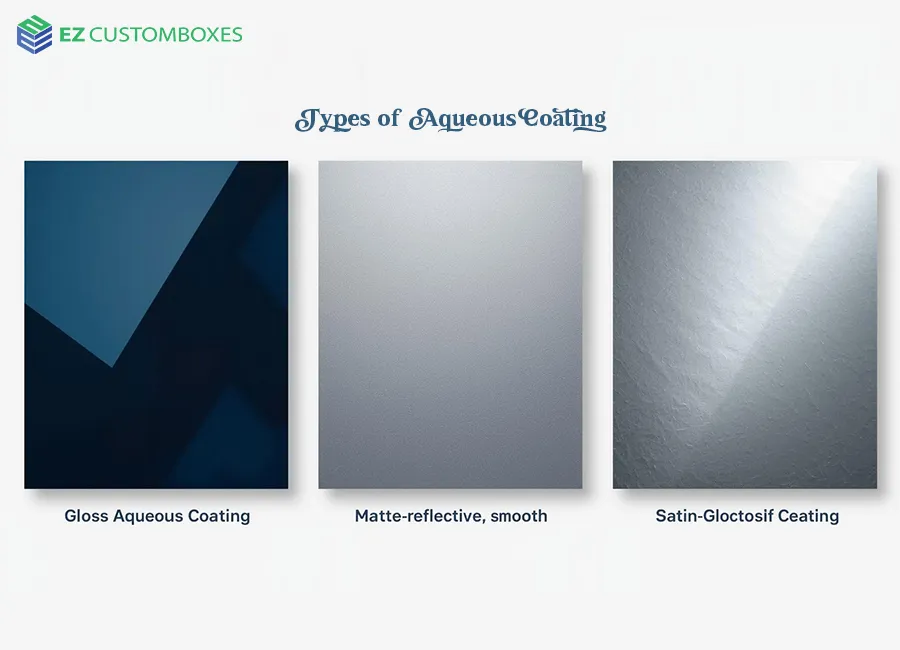

Types of Aqueous Coating

There are various types of aqueous coatings available. They are discussed below:

- Gloss Aqueous Coating

This tends to be a quick-drying, water-based liquid that gets put on printed materials. The packaging has a shiny and reflective, high-gloss finish. Gloss aqueous coating enhances colors. It keeps the packaging safe from scuffs, smudges, as well as fingerprints. It is common for packaging, magazines, brochures, etc.

- Matte Aqueous Coating

This is a clear, water based liquid that gets applied on printed materials. It gives the packaging a non-glossy and low-luster finish which resists fingerprints. Matte aqueous coating enhances colors and gives the packaging a sophisticated appearance.

The main advantage of this coating is that it helps with readability as it minimizes light reflection. The printed material will therefore suit areas that have bright overhead lighting like offices, trade shows, etc. The glossy finish gives a distracting glare.

- Satin/ Semi-Gloss Aqueous Coating

Satin aqueous coating or semi-gloss aqueous coating is a mixture of matte along with a high-gloss finish. It gives the printed materials a subtle sheen giving the packaging durability. It is common for luxury packaging and business cards.

Key Benefits of Aqueous Coating

The following are some advantages of aqueous coating:

Enhanced print durability - Many businesses consider aqueous coating as it gives enhanced print durability keeping the printed materials safe from scratches, fingerprints, smudges, as well as scuffs so that the quality of print remains durable.

Faster drying time - The water-based formula lets the printing dry quickly and it speeds up production as well.

Cost-effectiveness - AQ coating is generally less costly when compared to other coatings such as UV allowing it to be budget-friendly. It is often employed in-line with the printing procedure, therefore being cost-effective.

Eco-friendly and low VOC - Aqueous film coating is a water-based and low-VOC (Volatile Organic Compound) option when compared to solvent-based coatings. It gives less waste and needs limited toxic cleaning.

Food-safe and recyclable compatibility - Food businesses prefer this coating as it is water-based and safe for food whilst being recyclable.

Common Industries using Aqueous Coating

The following are some industries that prefer aqueous coating for packaging:

- Food and beverage

- Pharmaceutical

- Cosmetic and personal care

- Retail and e-commerce

- Printing and publishing

- Packaging and labeling

- Consumer electronics

- Luxury and gift packaging

- Tobacco and CBD packaging

- Healthcare and medical devices

Aqueous Coating vs Other Coating Types

|

Types |

AQ Coating |

UV Coating |

Varnish |

|

Speed of drying |

Dries quickly |

Dries instantly |

Takes the longest time to dry |

|

Coating Area |

Only available in flood coating |

Available as flood or spot coating |

Available as flood or spot coating |

|

Solution Base |

Non-toxic water-based solvent |

Chemical-based solvent containing polyethylene |

Either water or chemical based solvent |

|

Finishing Impact |

Matte, satin, or gloss |

Matte or gloss |

Matte, satin, or gloss |

|

Yellowing Impact |

Not likely to get yellow |

Does not yellow over time |

Yellowing can occur |

Aqueous Coating vs UV Coating

AQ coating and UV coatings are able to protect prints. They differ when it comes to their composition, curing, finish, as well as cost.

Aqueous tends to be water-based and dries by evaporation. It is flexible and more eco-friendly. It often gives a matte or satin finish and that at a lower cost.

When looking at UV, it employs resins that are cured by UV light to dry instantly. It gives high gloss and superior chemical resistance. The results have vibrant colors. It can be more costly to get and can sometimes be brittle.

Aqueous Coating vs. Varnish

Aqueous coating dries quickly and is water-based. It is eco-friendly and gives amazing protection. It has non-yellowing properties. It is better for flood coating. On the other hand, traditional varnish is usually oil-based and dries slowly. It can yellow and contains higher VOCs if it is oil-based. However it gives more precise spot application. It can enhance color depth as well.

The main difference is in the composition with AQ being water-based and varnish being oil or solvent based. AQ dries quicker and is more eco-friendly as well.

Aqueous coating vs matte lamination can even be considered. As said above AQ coating tends to be water-based whilst matte lamination employs a plastic film to enhance durability. It gives the printed material a more luxury feel and therefore is more suitable for high-use products. It is more costly and less eco-friendly when compared to AQ.

Common Application of Aqueous Coating

The following are some common applications of aqueous coating:

- Commercial printing including brochures, flyers, etc. for stronger durability when distribution is occurring.

- Used for packaging and cartons - Keeps product boxes safe and can protect food items, cosmetics, etc.

- Book covers and magazines - It can be used for publications to withstand frequent handling.

- Food packaging - Protects food products

- Pharmaceutical packaging - Can keep pharmaceuticals safe

- Aqueous coating business cards are even popular

Is Aqueous Coating Environmentally Friendly?

Yes, aqueous-based coating systems are environmentally-friendly. This is because it is water-based and low in Volatile Organic Compounds or VOCs. This enhances the recyclability properties of the packaging. However it is not totally plastic-free. Its compostability even varies by formulation.

When compared to solvent-based choices, it gives protection and dries quickly whilst releasing lower emissions.

It employs water like a solvent and limits dangerous chemical content in the packaging. It gives out lesser VOCs when compared to traditional varnishes resulting in cleaner air.

It lets paper products get recycled in an easier way when compared to plastic linings. It is said to be generally non-toxic and so safer for people and the Earth.

How to Choose the RIght Aqueous Coating

A business needs to choose the correct aqueous coating according to its needs. This depends on the desired finish. A business may want a glossy, matte, satin, or soft-touch finish.

The function of the coating must be kept in mind. You may want it to enhance the protection of the box. Some businesses may want it for scuff resistance or for some special impacts such as dry-ease.

It is important to balance aesthetic appeal with a brand’s practical requirements for durability, vibrancy, and elegance in the printed materials.

You can figure out what your goals are and choose the best one according to this. For instance if you want a high shine impact for vibrancy you can select aqueous gloss coating. If a brand wants understated elegance, it can consider matte or satin. For a velvety feel you can get aqueous soft touch coating, and for functionality you can consider dry erase or pencil receptive.

Coatings are able to hide flaws present on rough and inexpensive paper. For instance on really absorptive stock, a business can get gloss aqueous coating with enhanced drying speed.

Water-based AQ coatings tend to dry quicker and may be more cost-effective than UV coatings.

Expert Insights: When Should You Use Aqueous Coating?

A business that is looking for cost-effective protection whilst getting an attractive design can consider AQ coating. This is on items that are frequently handled such as brochures, business cards, food packaging, etc. If you require fast drying then choose this one. Aqueous coating digital printing may be smudge resistant.

A major advantage of AQ coating is its eco-friendly properties that makes many people drawn to it.

AQ coating is cost-effective and can be chosen by businesses that are still trying to establish themselves. If you do not have time and want quick results then AQ coating will help you out.

AQ coating is suitable for food items as it has a low plastic content that prevents sogginess and can enhance the freshness of the product.

Conclusion

Aqueous coating in printing tends to be a popular coating option trending in the packaging industry. It gives a water-based clear finish when put on printed materials. The coating is able to enhance the protection as well as look of the printed materials. It is often employed in packaging because it is cost-effective. It is even environmentally-friendly and so is trending amongst eco-conscious businesses and consumers. The coating is able to increase the durability of the printed materials providing businesses with strong packaging capable of protecting the product.

Frequently Asked Questions

What is aqueous coating used for?

Aqueous coating tends to be a water-based varnish that is employed in printing as well as packaging to keep surfaces protected and to enhance the look of the packaging whilst improving durability. It gives the packaging a gloss or matte finish and resists smudges plus scuffs.

Is aqueous coating safe for food packaging?

Yes, it is generally safe for food packaging as it is water-based and non-toxic. It is even eco-friendly and can keep food items safe from moisture, grease, as well as scuffs.

Is aqueous coating better than UV coating?

The option depends on one's needs. UV coating provides superior gloss, durability, as well as spot coating options. On the other hand, aqueous coating tends to be more eco-friendly and cost-effective. It is preferred for flood coating options and prevents wrinkling and yellowing from occurring.

Does aqueous coating make prints waterproof?

No, aqueous coating will not make prints waterproof as it is water-based. It provides resistance to only minor splashes, fingerprints, as well as smudges. However prolonged liquid exposure can harm it.

Can aqueous coating be recycled?

Yes, aqueous coating is generally recyclable along with compostable. This makes it a sustainable alternative when compared to plastic linings as it is water-based and can break down easily.

How much does aqueous coating cost?

The coating varies by application. However, for printed materials such as business cards, it can be affordable. It is regarded as being cost-effective when compared to UV coatings.

Ethan Robert works at EZ Custom Boxes as their digital marketing manager. Having a solid background in SEO, content strategy, and eCommerce growth, he specialises in using creative packaging content and data-driven campaigns to drive online visibility and brand interaction.