Accurate box measurements are a game-changer. Your style, design, and even the protection demands on the right box size. The choice of the box affects everything from product protection to shipping cost and brand image. EZ Custom boxes help you to design the perfect packaging that will best fit for your product. But the first step for crafting the boxes is to get the proper dimensions. After the measurement, the production timelines, material usage, and printing layouts are decided accordingly. This guide walks you through all the basics and advanced tips for measuring boxes and packaging sizes, helping you avoid costly mistakes and delays.

How Do You Properly Measure a Packaging Box?

The first thing to note is to measure the box from inside. Use a measuring tape or ruler to measure length, height, and width. Length is the longest side of the box. The perpendicular or the shortest side is the Width, and height is measured from the base to the top edge. Always use the same unit of measurement (inches, centimeters, etc.) for all dimensions. Always measure the box on a flat surface and also leave some room in measurements for cushioning. Internal dimensions do not include the thickness of the material, so if you're dealing with rigid boxes or thick cardboard, this distinction is especially important.

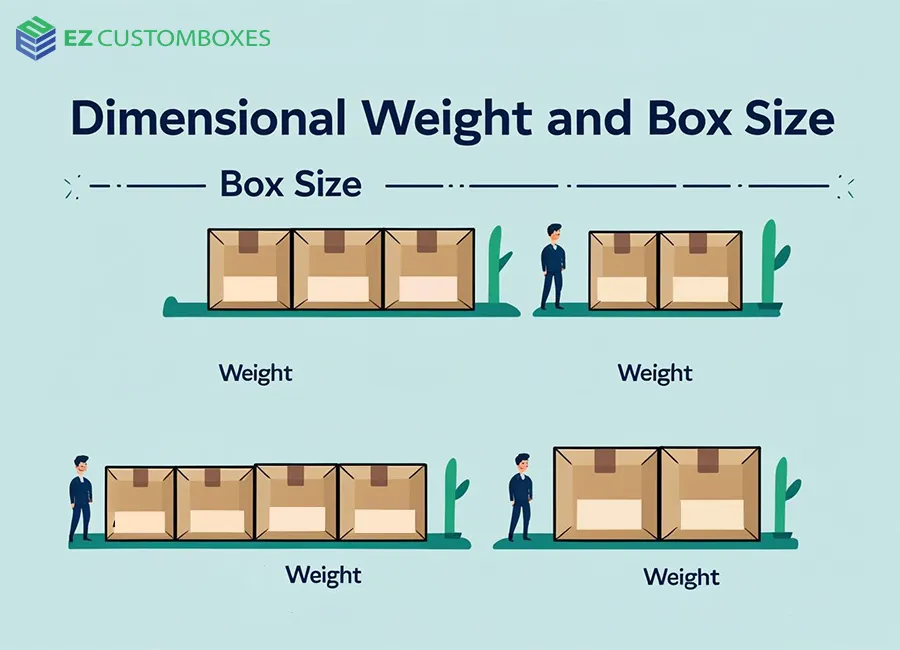

How Is Dimensional Weight Related to Box Size?

Shipping carriers usually use dimensional weight which is also known as DIM weight as a pricing technique rather the its actual weight. Such as if the large but light weight packaging the shipping cost will be according to their dimensional weight, meaning the amount of space the package occupies.

Formula to calculate DIM weight: (Length × Width × Height) ÷ Dim Factor

For most couriers, the dim factor is 139 (for inches). If your DIM weight is higher than the actual weight, the shipping charge will be based on DIM weight.

Why Does the Orientation of Measurements Matter?

There is a standard way to list measurements:

Length × Width × Height

It's necessary to write this in the correct order. The correct measurements need to craft the box, and if there is a mix up of height and width, this could lead to wrong boxes which will not match to the product shape.

How to Measure an Open-Top Box?

To measure the open top boxes, we need the same Length, Width, and Height. Sometimes depth is used instead of height.

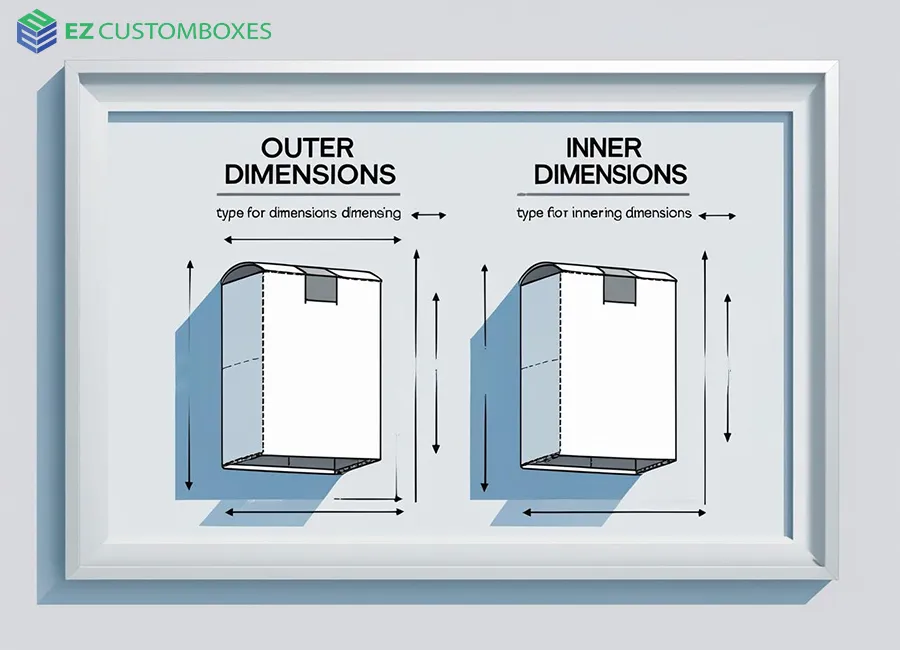

What’s the Difference Between Outer and Inner Dimensions?

Inner dimension refers to measurements of the internal space, meaning the usable space inside the box, whereas the dimensions of the outside refer to measurements of the external surface, which also include the thickness of the box walls. Think of it as the difference between the size of the whole object and the space it encloses. Before crafting the box, both inner and outer dimensions is important.

For example:

- Inner: 10" × 6" × 4"

- Wall thickness: 0.25"

- Outer: 10.5" × 6.5" × 4.5"

How to Handle Irregular Product Shapes?

For customized boxes, the measurements are crucial. For uneven shapes of the products here's how to measure for custom packaging.

- Measure the length, width, and height of the product.

- Leave cushion on all sides (usually 0.5-1 inch)

- Consider using custom inserts or foam padding to keep the item organized inside.

How Does Box Thickness Impact Internal Size?

Boxes are made of different materials such as corrugated board, chipboard or rigid board. The thickness of each material varies and also affects the inner space. This is the reason the internal dimension should be used for planning. Always clarify the board grade and thickness during discussions with your packaging supplier to get the perfectly fit custom boxes for your product.

Can I Visualize My Box Before Production?

We know that brands are sometimes not sure about their measurements, so we are here to help you. EZ custom boxes provide you with the digital or physical samples before ordering for bulk.

Calculating the Total Box Surface for Printing.

The boxes are also used as a canvas where brands tell their story. So, before crafting, it should be clear how much surface area would be available for the printing. Here is the formula used for a regular box to calculate the printing surface area:

Calculate the area of each face:

- Top and Bottom: Area = length * width.

- Front and Back: Area = length * height.

- Left and Right: Area = width * height.

This gives you the total outer area (excluding the flaps), helping you estimate costs for full-color printing or lamination.

What If I Want a Box with a Window or Custom Cut?

For the box having a window or custom cut, the measurements should be different. You’ll need to:

- Also, calculate the window size and position.

- Mention the material for the window to calculate the thickness

These little detail helps the manufacturers design the box that is both functional and stylish.

Why Is Box Sizing Important for E-commerce?

Oversized boxes cost more to ship and store. So it is necessary to get the right size boxes that reduce shipping costs, minimize material waste, and also improve customer satisfaction. That's why brands selling online must work closely with packaging companies to optimize their box dimensions for every product type.

What If I Use Inserts or Dividers?

If you are planning to use foam, cardboard or molded plastic inserts, it should also be calculated.

- Find the dimensions of the product

- Also, add an insert space

- Also include cutouts, holes, or cavities if needed.

These measurements need to be exact to ensure a snug fit and professional look otherwise, the brands have to suffer.

Ready to Design the Perfect Box?

The success of any packaging depends on accurate box measurement. At EZ custom boxes, we have experts which helps you get the right measurements and design the perfect boxes. Reach us and let us help you create the packaging that your product deserves.

Ethan Robert works at EZ Custom Boxes as their digital marketing manager. Having a solid background in SEO, content strategy, and eCommerce growth, he specialises in using creative packaging content and data-driven campaigns to drive online visibility and brand interaction.