Mylar bags are one of the smartest ways to store food for a long. These bags are the perfect combination of beauty and saving the food inside. They are shiny bags with a strong seal that keep the air, moisture, light, and even other contamination out and enhance the shelf life of the product inside.

At Custom Boxes, these bags are carefully designed with a strong sealing option that will protect the food inside and save your money, time, and effort. This guide will teach you how to seal Mylar bags correctly and give you all the tips and tools you need.

What Are Mylar Bags?

Mylar is a special kind of plastic known as BoPET. These bags are durable, tough, and known for their excellent barrier properties against light, air, and moisture. These bags are available in many different sizes and thicknesses. When used with food-grade aluminum layers, it becomes one of the best materials for long-term food storage. These bags are best used for storing rice, beans, Oats, pastas, powdered milk, spices and much more.

Why Is Sealing Important?

Food gets damaged quickly if it’s not packed properly. Even a small amount of air or moisture gets inside, making the bacteria, mold or insects grow inside. According to a 2024 food storage study by the U.S. Emergency Preparedness Group, improperly sealed Mylar bags had a 30% higher spoilage rate within just 6 months. This shows that Mylar bags are not an option but a need.

What You’ll Need To Seal Mylar Bags

Before knowing how to seal Mylar bags we should know what the requirements are or right tools for proper seal.

Required Items:

- Use high-quality Mylar Bags

- Oxygen Absorbers to remove the air inside the bag

- A heat sealer is needed to seal it properly

- The best printing technique for printing outside the bags.

Step-by-Step Guide to Sealing Mylar Bags

Let's delve into the process of sealing the Mylar bags to ensure they're perfect for storing food for an extended period.

Step 1: Choose the Right Size Bag

The first step is to choose the right size of the bag. You can get the custom sizes just perfectly match your product requirements from EZ Custom Boxes.

Tip: Thicker bags (5 mil or higher) last longer and seal better.

Step 2: Add Oxygen Absorbers

If a small amount of the air can harm the product inside so oxygen absorbers are dropped inside the bag. This will help in removing any leftover air and make it totally air-tight. “Oxygen is the enemy of food storage,” says Dr. Haley Finn, Food Microbiologist, in a 2023 Journal of Safe Preservation study.

Adding Nitrogen Flushing

Some food packers also use Nitrogen flushing. Usually, when packaging snacks, coffee or even pet food, the air inside the bag is replaced by nitrogen. It reduces the risk of producing molds and bacteria. It also gives a puffed and professional look.

Step 3: Seal the Bag with Heat

The most important step is to perfectly seal the bags. We use professional and advanced heat sealing machines that are best for making the process fast, consistent and also airtight precision. With the high pressure and controlled heat, the machines will perfectly seal the bags without damaging them.

Continuous band sealers automatically seal hundreds of units per hour. For sensitive food items such as medical-grade items, dehydrated meals or powdered items, the vacuum-sealed packaging is preferred. Vacuum chambers remove the air entirely before sealing.

At our company, our team performs leak tests and visual inspections to ensure the seals meet the safety standard. We partner with trusted manufacturers who ensure that our products are ready to be sealed efficiently and are also best suited to preserve food in every kind of environment. Some seals are even double-lined or reinforced is best for heavy-duty bags. We know that perfect sealing is the foundation of long-term preservation.

What Types of Seals Are Used in Mylar Food Bags?

-

Straight Seal: Use for flat storage

-

Double Seal: provides more safety from air or moisture

-

Zipper Seal (With Heat Seal on Top): Used for re-sealable food bags

Step 4: Test the Seal

To make sure that each bag is properly sealed, strict quality control tests will be made.

- One of the most common methods is the “burst test,” where pressure is applied to the bag until it breaks. This shows the strength of the bag.

- Vacuum leak test, the bag is placed in a vacuum chamber, and it shows if there is a leak through the seal. If the bag expands or bubbles form, it means it is not sealed properly.

- Dye penetration testing, in this test the manufacturer applies a colored liquid to the sealed edge, and if it leaks through invisible pinholes shows that it's not sealed properly.

- Automated Vision systems make sure that there should be no wrinkle, gaps or uneven closures.

We make sure that our Mylar packaging meets all the professional standards and they are seal- rest ready and ready to protect the food inside.

Common Mistakes to Avoid

- The bag is overfilled

- Storing the bags in humid places

- Ignoring the oxygen absorbers

- Leave any small wrinkle in the seal

Even a small mistake can ruin the whole bag, so be careful and double-check each step.

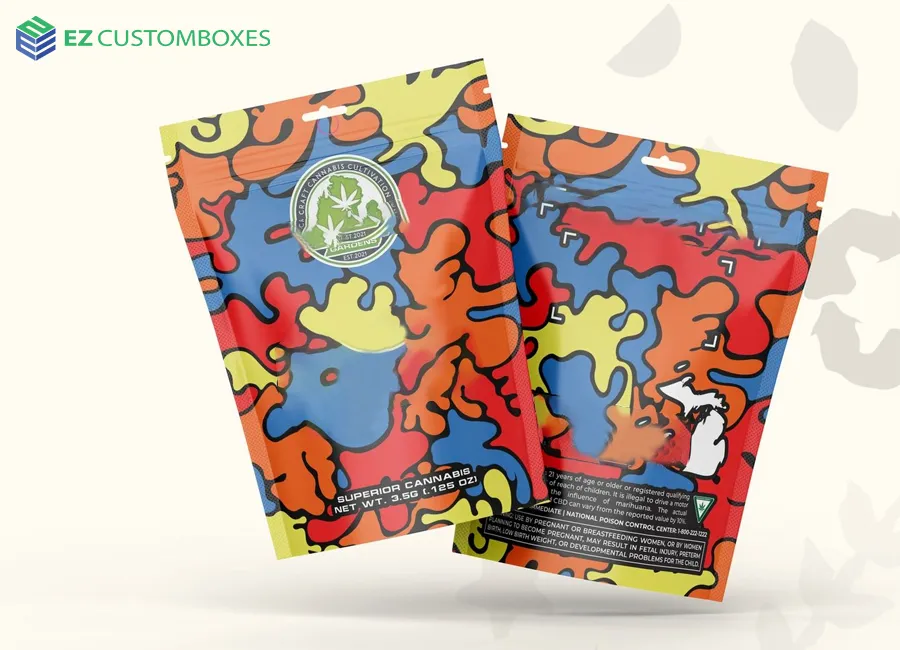

Custom Mylar Bags from EZ Custom Boxes

Here you will get the best quality Bags that are the best for keeping food safe. Customers will get the customized option for designing the bags with heat-resistant seals. These bags also have printed information that provides the customers with all the necessary information. We believe that these packagings are not only to keep the product safe but also to build the customer's trust. “Good food storage starts with smart sealing.” Properly sealed packaging is the key to keeping the food safe, fresh with all its taste. Order your boxes from none other than EZ Custom Boxes to seal your future with confidence.

Ethan Robert works at EZ Custom Boxes as their digital marketing manager. Having a solid background in SEO, content strategy, and eCommerce growth, he specialises in using creative packaging content and data-driven campaigns to drive online visibility and brand interaction.

.webp)